- WHEEL TECHNICAL INFORMATION

- 2piece wheel manufacturing process

- 1

Aluminum circle material made by SSR original recipe for rim part

- 2

Into the loader

- 3

Applying the working lubricant

- 4

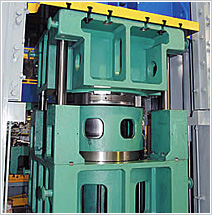

Into press machine (max 1,200t) by robot arm

- 5

Deep draw press

- The circle material becomes cilyndrical shape.The thickness of material is equalized.

- 6

Cooling

- The drawn material is high temparature because of high pressure press and goes cooling process.。

- 7

Cutting

- 8

Roll forming process

- The rim part formed by roll forming machine. Light weight and high rigidity rim is finishing.

- 9

Parts of 2piece wheel are finished.

- 10

Parts of 2piece wheel are finished.

- The first process of assembling is heating.The rim part is heated and spread with keeping roundness for center disk inserting.

- 11

Assembling

- The automatic insertion machine puts the center disk to the indicated inset.

- 12

Automatic Welding

- 13

Finished